top of page

1/3

Our expertise

With extensive experience in pioneering glass solutions, we are dedicated to advancing material innovations. Discover how TLC Glass leverages its unique expertise and cutting-edge technology to set new standards across various industries.

Compliance certificate

Our manufacturing facility is ISO 9000 and ISO 14000 compliant, ensuring that our products, processes, and systems meet all specified standards and regulatory requirements. Our commitment to excellence and compliance fosters trust and confidence in our products.

Custom design and processing

We offer comprehensive services, including design, melting, and processing of glass, tailored to address the unique challenges of each company. Our diverse range of glass products is designed to meet a variety of needs and challenges.

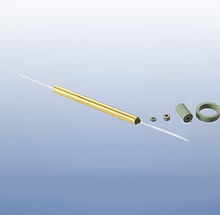

Glass Sealing, Glass Soldering

Sealing and soldering glass are primarily used in hermetic sealing between glass, metal, and ceramic. These materials are essential for gap welding, plane bonding, and electrical insulation sealing, addressing diverse product requirements. The sealing glass ensures robust and durable seals, while the soldering glass facilitates precise and reliable joints. Both sealing glass and soldering glass cater to various temperature performance needs. Customers can customize specifications according to their product structure, ensuring optimal performance and compatibility in different applications.

Product gallary

Glass Forging Lubricants

Glass forging lubricants and insulation coatings for metal hot forging processes are essential for various types of metals at different temperature ranges in various forging processes. These glass forging lubricants provide excellent protection, lubrication, and insulation during metal heating and forging. By using glass forging lubricants, the surface quality of the forged metal is significantly improved, and the service life of the molds is extended. The application of glass forging lubricants ensures optimal performance and durability in metal forging operations.

Glass to Metal Connetor

Glass forging lubricants and insulation coatings for metal hot forging processes are essential for various types of metals at different temperature ranges in various forging processes. These glass forging lubricants provide excellent protection, lubrication, and insulation during metal heating and forging. By using glass forging lubricants, the surface quality of the forged metal is significantly improved, and the service life of the molds is extended. The application of glass forging lubricants ensures optimal performance and durability in metal forging operations.

bottom of page